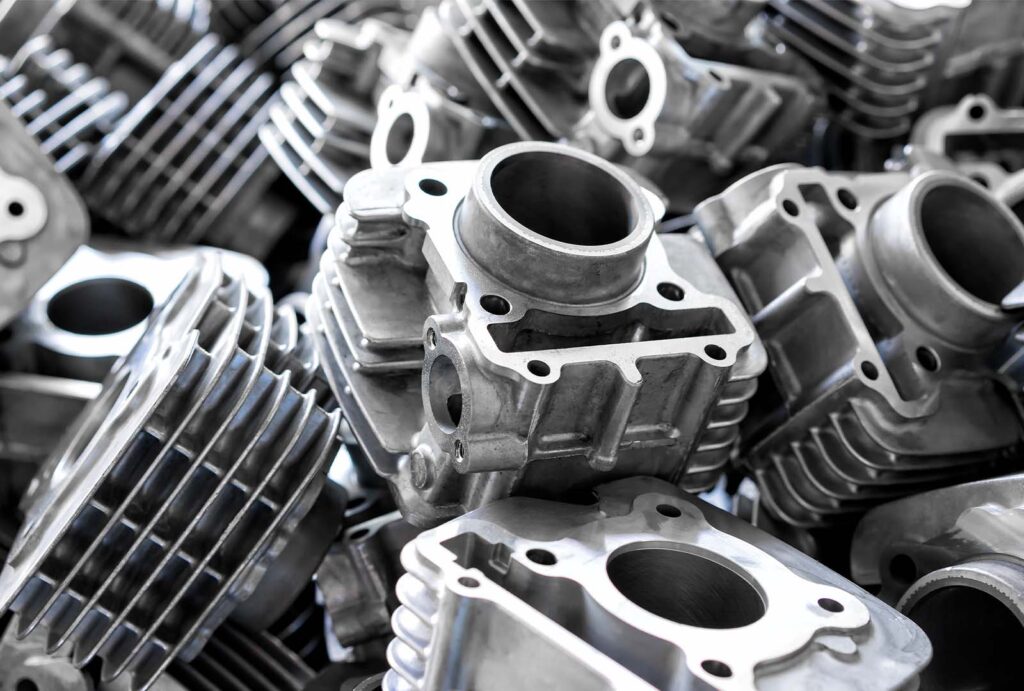

Die casting is a crucial manufacturing procedure that has a major contribution to Malaysia’s industry. The process is known for its efficacy and capability to create complicated metal parts that are made with great precision the process has evolved into the foundation of many sectors in Malaysia that include electronics, automotive as well as consumer goods. It involves injecting the molten metal in a die or mold under extreme pressure in order to create products with a smooth with a perfect finish, and extremely tight tolerances. Malaysia due to its central position and growing manufacturing industry has grown into a center of die casting firms serving both local and international market. The latest manufacturing technology has transformed the method by which metal components are manufactured and offers cost-effective solutions for large-scale production.

One of the major reasons for the rapid growth of the die-casting industry within Malaysia is the rising demands from the automobile industry. Automotive manufacturers need high-end, light and long-lasting metal parts to construct vehicles. Die casting is the ideal solution. With this technique, pieces such as engine blocks transmission cases and other structural parts can be made effectively and at a high level of accuracy. Malaysia’s close proximity to the major automotive markets throughout Southeast Asia makes it an perfect location for die-casting businesses to flourish. In addition, the increase of electronic vehicle (EV) manufacturing has increased the need for die-cast parts, because the vehicles heavily rely on aluminum to help reduce weight and boost the efficiency of energy.

The electronic manufacturing industry is booming in Malaysia is a major factor that is driving demand for services in die casting. Malaysia has been for a long time a major hub in electronics production, and die casting is vital roles in making high-quality components for every aspect of smartphones and home appliances. Die casting’s ability to produce intricate, tiny-scale components with precise tolerances is essential for electronic gadgets that require precision. In addition, the increasing technology of miniaturization is resulting in an increasing requirement for ever more sophisticated die-casting components. Malaysian die casting firms have the capacity to tackle the challenges ahead, providing creative solutions that meet the ever-changing demands of the electronic industry.

Innovation and sustainability have become increasing important to the Nickel chrome plating Malaysia business, and Malaysia is not an any different. With environmental issues growing the majority of die casting firms within the country are adopting more sustainable practices in order to lower the carbon footprint of their operations. Utilizing recycled products, efficient production methods that use less energy and techniques for reducing waste are becoming more widespread in the business. Furthermore, advancements in die casting technologies, including the adoption of coolers that are more efficient and better mold designs, can boost productivity as well as reducing environmental impacts. Die casting in Malaysia has not just contributed to Malaysia’s economic growth but is also collaborating with international initiatives to promote sustainability in manufacturing.

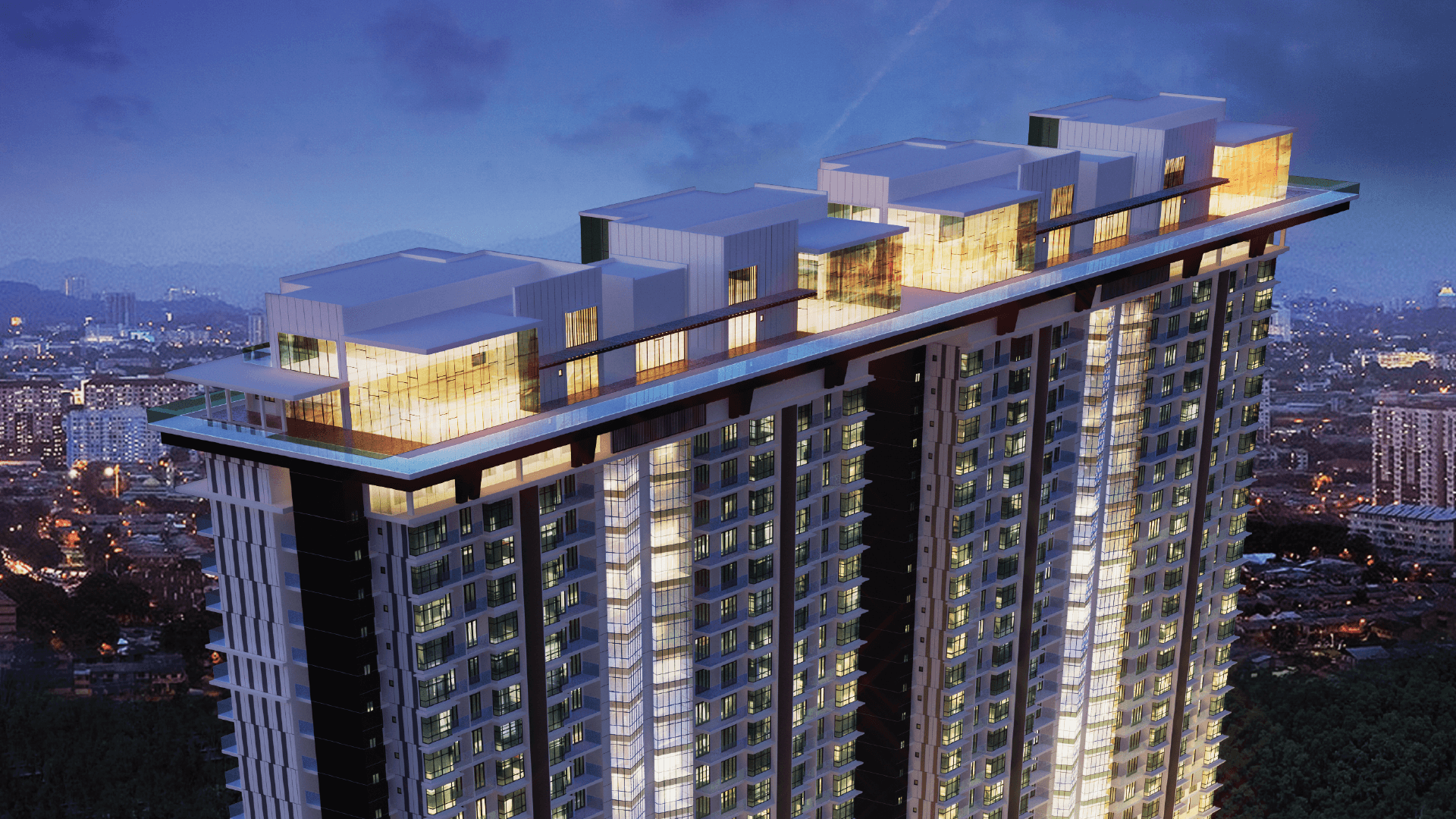

Die casting industry in Malaysia is a thriving industry that has a highly skilled workforce as well as an advanced infrastructure to support expanding the business. The Malaysian government is actively supporting industrial growth with initiatives including tax incentives, development of infrastructure as well as partnerships with international corporations. It has allowed local casting firms to make investments in cutting-edge equipment and technologies, positioning Malaysia as a leading player within the international market for die casting. Furthermore, Malaysia’s emphasis on technical and educational training is credited with creating the workforce with a solid understanding of the latest manufacturing methods and further assisting in the expansion of the business.

In the end it is clear that die casting is an essential part of Malaysia’s economic ecosystem. It plays an important function in areas such as electronic and automotive as well as consumer items. Malaysia’s strategically located as well as the growing demand for lightweight and precise components, as well as its dedication to sustainable development and innovation create a hub of die casting processes. With the demand worldwide for top-quality metal components is increasing the Malaysian die casting industry can meet the demands of customers with advanced manufacturing methods and an experienced workforce. In the future, the business will continue to grow adopting new technology as well as sustainable techniques to ensure its position as a leader in the world market.